Thermoplastic compounds

Description

Thermoplastic compounds are a class of material whose base resin is of thermoplastic nature, formed by polymer chains interacting through intermolecular interactions (Van Der Waals forces) and generating a 3D structure, more or less entangled. Depending on the type and intensity of these interactions, the polymer can present amorphous and/or crystalline structures. Polymer chains of the first category are generally randomly arranged and responsible for the elastic behaviour of the material, whereas the second ones are more organised and tight, yield the materials resistance and strength.

The spectrum of properties that this class of materials can present is definitely vast in terms of mechanical, thermal, electrical properties and transformation technology. Along with the base resin there are mineral fillers, fibres, modifiers and flame-retardants affording the specific requirements of each single application and stabilising additives to prevent the deterioration during the process and the final application of parts. The high throughput typical of thermoplastic compounds transformation processes often requires the employment of process aids such as plasticisers.

The main properties of thermoplastic materials are:

- Thermoformability

- Lightness

- Outstanding resistance or flexibility depending on the application

- Excellent finishing quality (surface, details, touch)

- Outstanding formulation versatility

- High or low thermal conductivity based on the formulation

- High resistance of electrical conductivity by using insulating or conductive charges

- Ease in colouring

- Long life

Processing

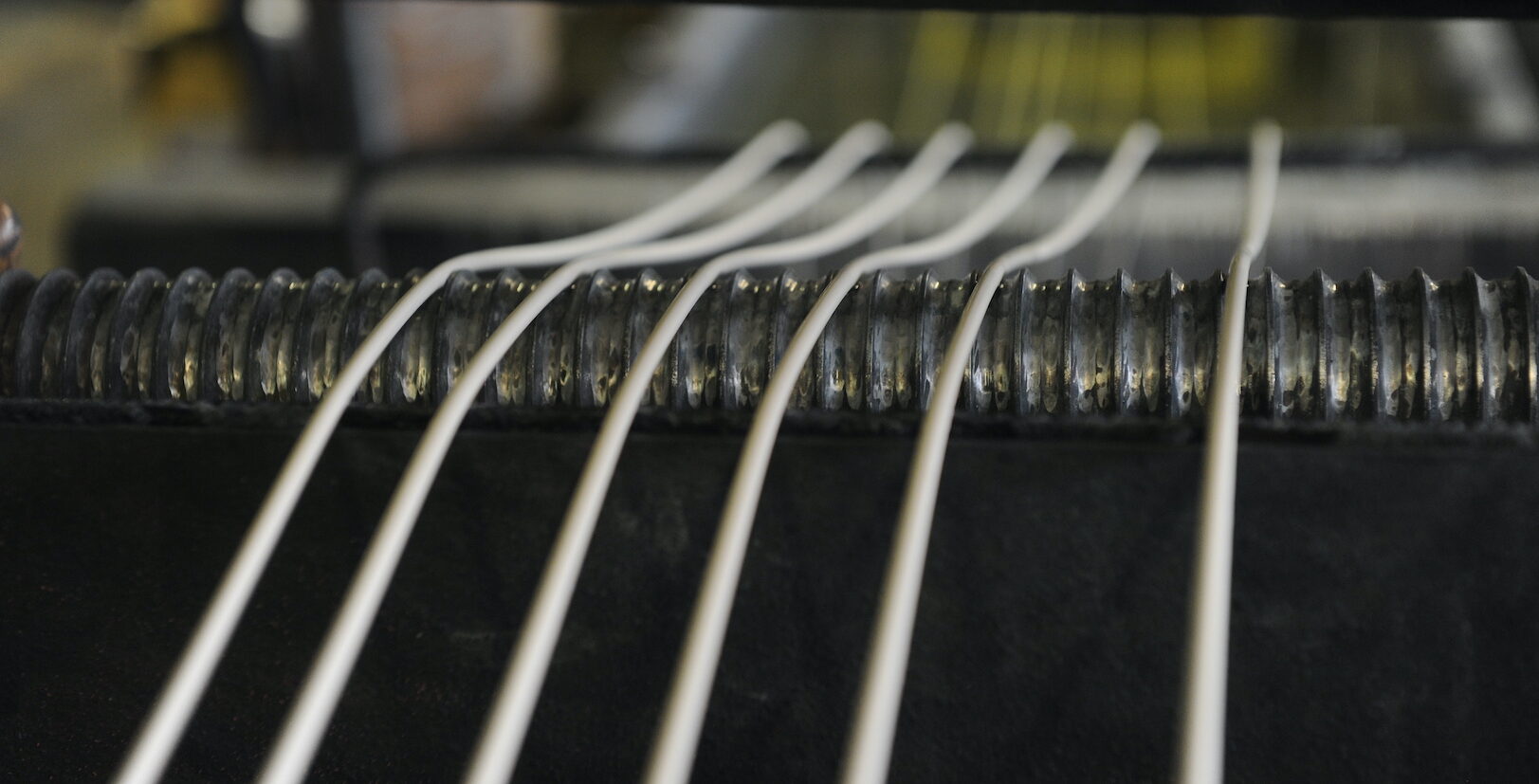

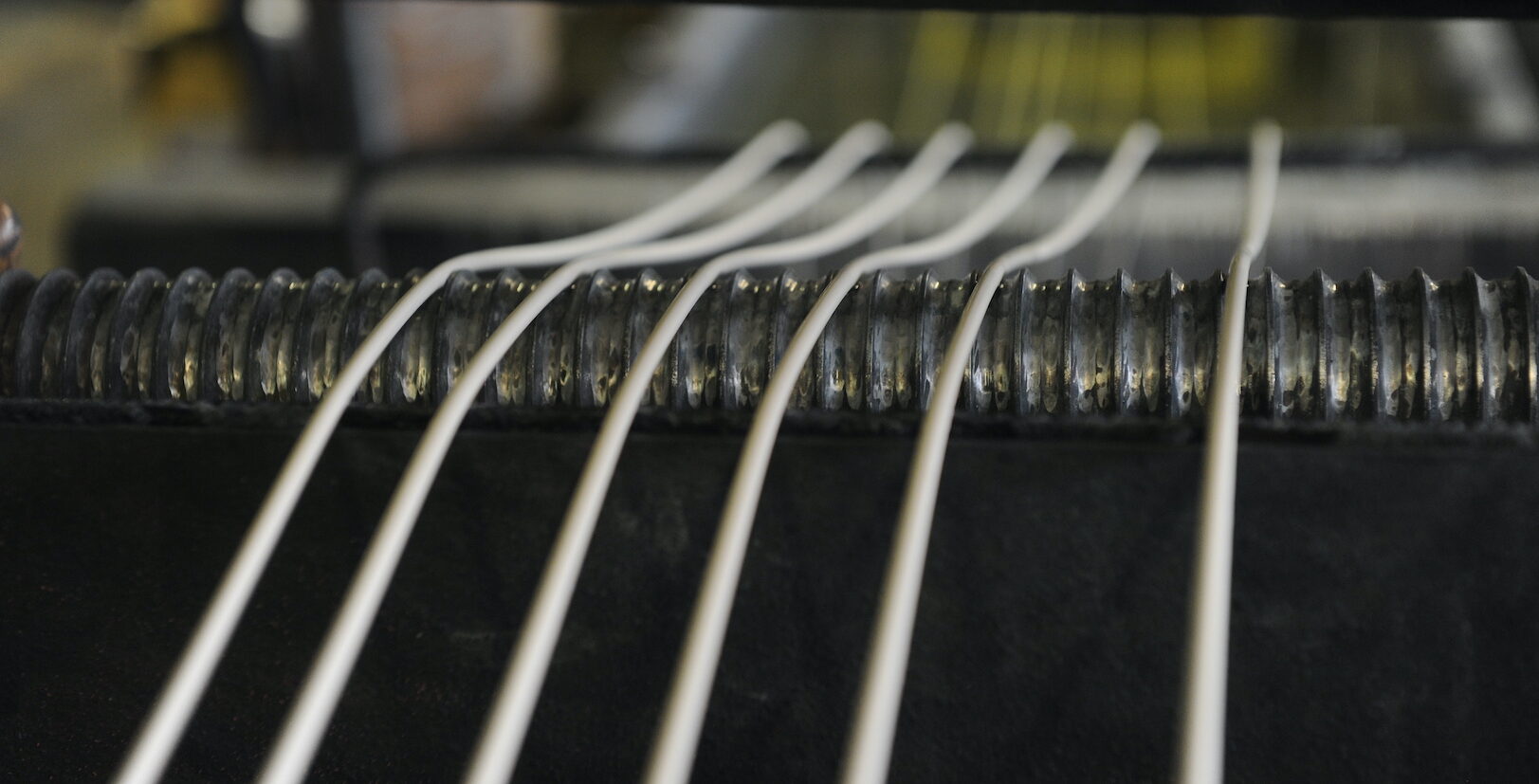

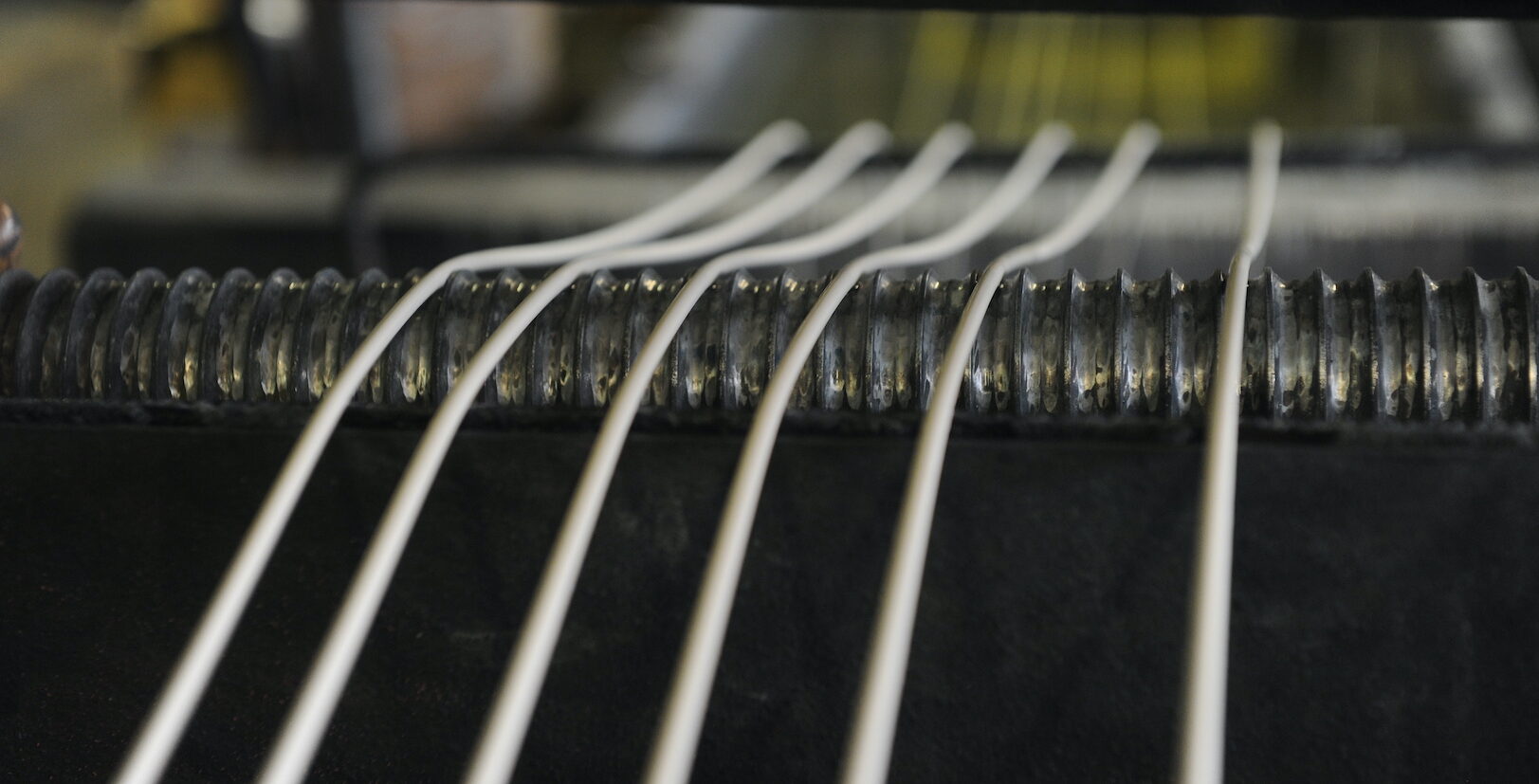

Thermoplastic materials are generally processed by injection moulding, blow moulding, film casting, extrusion and pultrusion. Thermoplastic compounds do not require a reticulation process and are generally supplied in granules that soften and get fluid upon heating. This characteristic allows recycling the material without damaging too much the physical properties.

Processing

Thermoplastic materials are generally processed by injection moulding, blow moulding, film casting, extrusion and pultrusion. Thermoplastic compounds do not require a reticulation process and are generally supplied in granules that soften and get fluid upon heating. This characteristic allows recycling the material without damaging too much the physical properties.

Conductive compounds

Thermoplastic conductive compounds are used for producing manufacts for which it is necessary to dissipate static charges to protect them from damages that could be caused by electricity.

Conductive compounds contain carbon black, which makes thermoplastic materials electrically conductive.

By changing the type of carbon black used in the compound, the percentage and the degree of dispersion, it is possible to modulate the resistivity range of the thermoplastic material and, thus, the field of application.

We dispose of the following conductive compounds:

- PVC for flooring;

- PVC

- PP for tubes

Market segment

- Automotive

- Industrial

- Energy

- Consumer goods

- Building & construction

- Home appliances