Fluoro-carbon rubber compounds

Description

Among the other rubber classes, fluoro-elastomers (FKM or FPM and FFKM) show the best properties in terms of resistance to fire and to chemical agents due to the high content of fluorine and to the intrinsic stability of the carbon-fluorine bond. Commercial grades of fluoro-elastomers are obtained from the radical polymerization of vinyl monomers. The most common are: difluoroethylene (VDF), tetrafluoroethylene (TFE), hexafluoropropylene (HFP), perfluoromethylvinylether (PMVE), 2-methoxyethylvinyl ether (MOVE), ethylene and propylene. The proper polymer in-chain dosing of groups with different steric hindrance and properties together with the employment of specific terminal chains allow modulating mechanical properties, their behaviour at low temperature, chemical resistance, the type of reticulation and processability. The rigidity of fluoro-elastomer polymer chains determines a peculiar plastic behaviour with a rather slow creep recovery and low resilience.

Fluroelastomer-based formulations are generally characterised by the use of non‑ or weak‑reinforcing fillers, both carbon blacks and white fillers, and by a low content of process aids.

These are some of the properties of fluoro-carbon rubber compounds:

- Steady service temperature up to +320°C also in contact with fluids

- Dynamic employment at low temperatures up to -45°C with some specific grades

- High compatibility with all type of fuels

- Excellent resistance to blow-by condensates

- High resistance to solvents, oils, acids and bases, both organic and inorganic

- Low gas permeability

- Excellent dielectric properties

- High resistance to fire

Processing

Fluoro-carbon rubber compounds are generally processed through compression or injection moulding depending on the type of article. Frequently, fluoro-elastomers are overmolded on metal parts. Another typical application is the preparation of hoses and tubes, by means of extrusion or wrapping and autoclave curing. The complex macromolecular architecture permits taking advantage of ionic reticulation mechanism using appropriate diamines or bisphenol curatives combined with specific activators, or radical reticulation mechanism using appropriate organic peroxides.

Processing

Fluoro-carbon rubber compounds are generally processed through compression or injection moulding depending on the type of article. Frequently, fluoro-elastomers are overmolded on metal parts. Another typical application is the preparation of hoses and tubes, by means of extrusion or wrapping and autoclave curing. The complex macromolecular architecture permits taking advantage of ionic reticulation mechanism using appropriate diamines or bisphenol curatives combined with specific activators, or radical reticulation mechanism using appropriate organic peroxides.

Market segment

- Automotive

- Industrial

- Oil & gas

- Agriculture

- Building & construction

- House appliance

- Consumer goods

- Health care

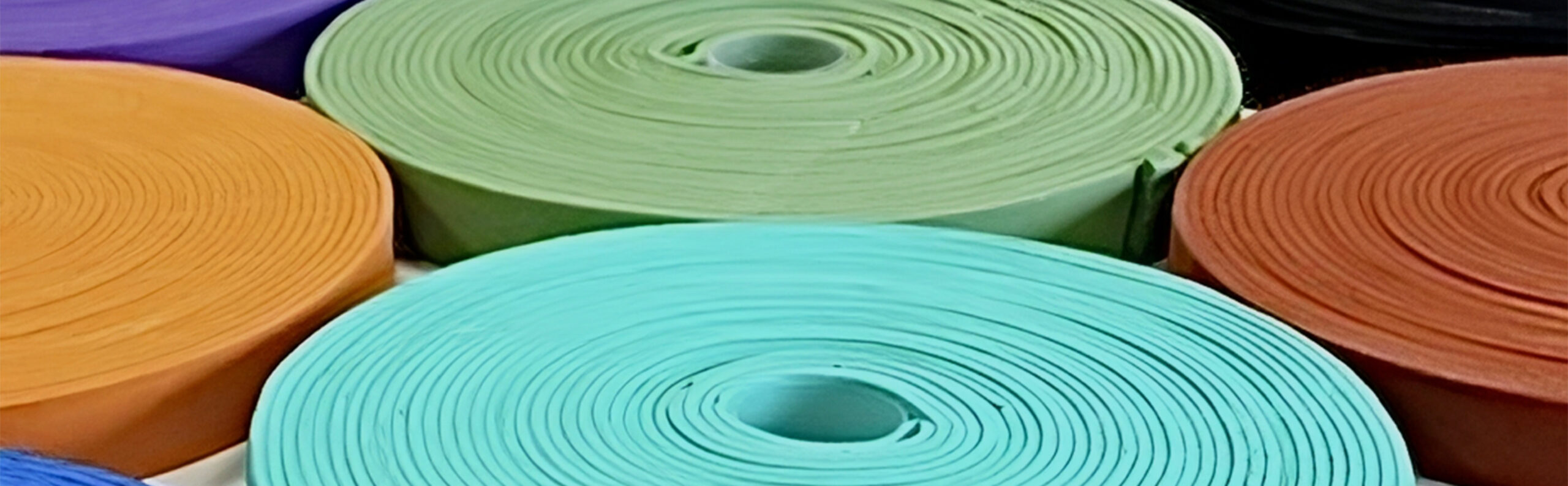

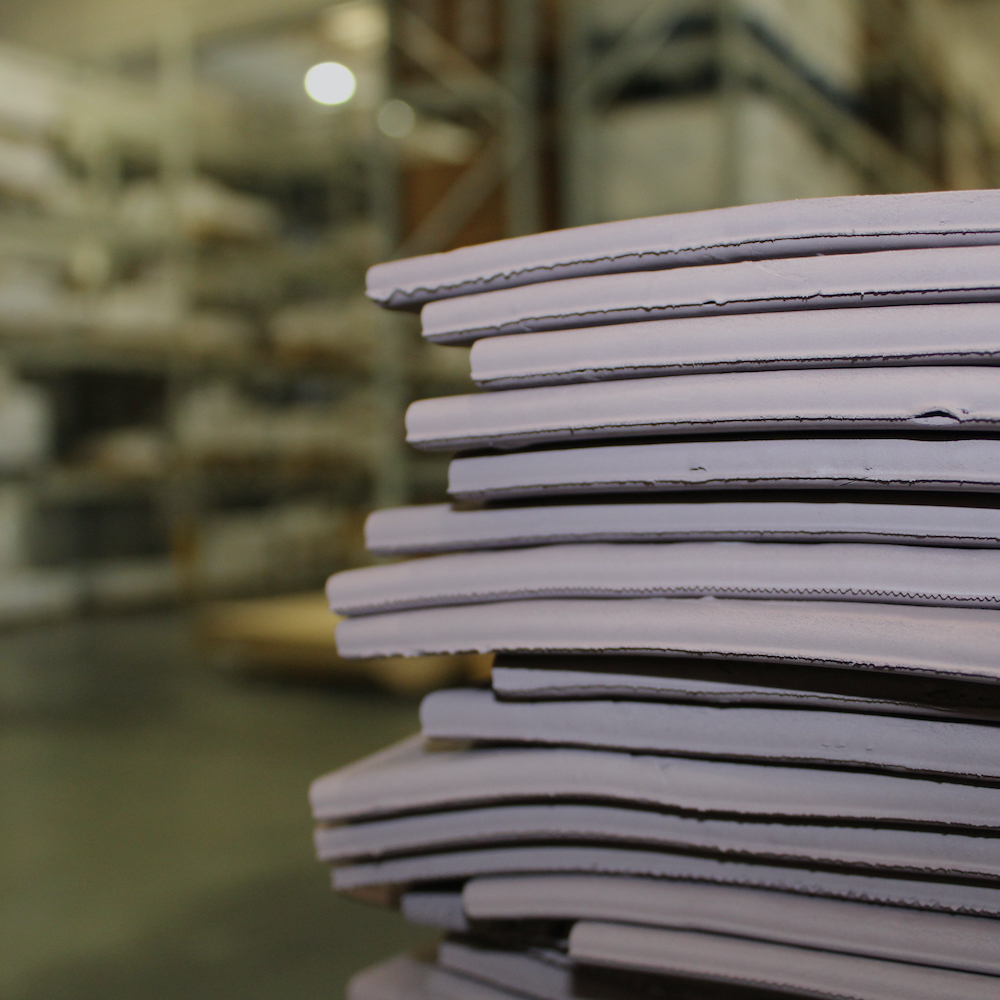

Packaging

| Width | 40 mm (± 5 mm) |

| Thickness | 6 mm (± 2 mm) |

*possibility of customization

| Width | From 30 mm to 60 mm |

| Thickness | From 5 mm to 8 mm |

*possibility of filter

*possibility of customization

| Width | 400 mm (± 5 mm) |

| Thickness | 6 mm (± 2 mm) |

*possibility of customization

| Width | 600 mm (± 20 mm) |

| Thickness | 6 mm (± 2 mm) |

| Length | 1000 mm (± 50 mm) |

*possibility of customization